Rigid Roof Panels Sandwich Polyurethane Injection Machine

| Power (kW): | 9kW | Machine Type: | Foaming Machine |

|---|---|---|---|

| Condition: | New | Product Type: | Foam Net |

| Voltage: | 380V | Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm |

| Weight (KG): | 2000 KG | Warranty: | 1 YEAR |

| After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | Key Selling Points: | Automatic |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Showroom Location: | Turkey, Pakistan, India |

| Applicable Industries: | Manufacturing Plant | Strength 1: | Self-cleaning Filter |

| Strength 2: | Precise Metering | Feeding System: | Automatic |

| Control System: | PLC | Foam Type: | Rigid Foam |

| Tank Volume: | 250L | Power: | Three-phase Five-wire 380V |

| Name: | Pu Foaming Machine | Port: | Ningbo For Pu Foaming Machine |

| High Light: |

sandwich polyurethane injection machine, 250L Polyurethane Injection Machine, sandwich polyurethane injection equipment |

||

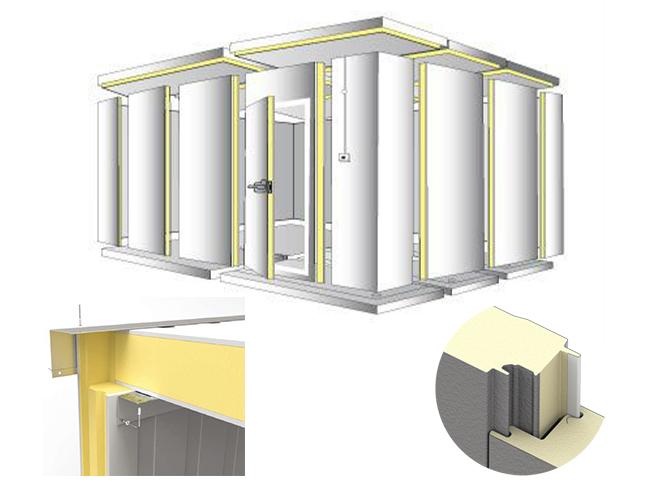

PU Polyurethane Foam Injection High Pressure Machine For Insulated Roof Panels Making Application: Panels consisting of metal-faced sandwiches with a polyurethane core are highly versatile in their uses thanks to their exceptional insulating properties. In addition to its application for the insulation of facades, roofs and floors, it is also applied in industrial buildings and cold stores. With their extra-high temperature stability, they achieve superior standards of fire protection in areas where conventional materials reach their limits.

Application: Panels consisting of metal-faced sandwiches with a polyurethane core are highly versatile in their uses thanks to their exceptional insulating properties. In addition to its application for the insulation of facades, roofs and floors, it is also applied in industrial buildings and cold stores. With their extra-high temperature stability, they achieve superior standards of fire protection in areas where conventional materials reach their limits.

Product Description: Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer's request various pours out of the machine.

This polyurethane foaming machine uses two raw materials, polyol and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

| No. | Item | Technical parameter |

| 1 | Foam application | Rigid Foam Sandwich Panel |

| 2 | Raw material viscosity(22℃) | POLY ~2500MPas ISO ~1000MPas |

| 3 | Injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 500~2500g/min |

| 5 | Mixing ratio range | 1:3~3:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | Mixing head | Four oil house,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/min System pressure 10~20MPa |

| 11 | Tank volume | 250L |

| 15 | Temperature control system | Heat: 2×9Kw |

| 16 | Input power | Three-phase five-wire 380V |

Product Features of High Pressure PU Machine:

1. Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2. Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3. Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4. Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5. High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6. Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors.

Mixing head:

The mixing head adopts floating mechanical seals, and its high shear mixing screw head, which can mix two materials (Polyurethane and Isocyanate) with better performance.The raw materials are stirred at high speed in the mixing chamber by stirring blades to achieve a mixing effect, so that the liquid is uniformly sprayed to form a desired product.

Electrical control system:

Adopting mcgs man-computer interface, setting the injection time,test time and pressure time and etc. Adopting Taiwan Fatek programmable controller and whole foaming machine automatic controlled, make metering unit, hydraulic unit, temp control system, tank agitator, mixing head injection coordinate the work according to the procedures, ensure process efficiency and reliable.  Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Visitors and Exhibitions:

We participated in many exhibitions of polyurethane raw materials, polyurethane foam products and polyurethane PU foam machines. Our products left a very good impression to everyone at the show, some customers even placed orders on the spot.

Certificate:

FAQ: 1. Are you factory or trading company?

FAQ: 1. Are you factory or trading company?

We are professional factory in PU industry with more than 10 years experience, covering high pressure pouring machine,low pressure foaming machine, pu spraying foam machine,pu elastomer casting machine and production line.

2. Where is your factory ?

Our Factory is located in Wuxi city, Jiangsu Province.

3. How can I get your factory?

By air: You can take a plan to WUXI airport from China, if you fly from Korea ,Japan, USA, Singapore, Taiwan, Thailand you will can directly fly to us.

By Train: You can stop at WUXI station, Not WUXI EAST station.

4. Do you provide pick-up service?

Yes, of course. If you are in Wuxi airport or station, we can arrange a special car to pick you up directly to our factory.