Concrete Tool Trowel Making High Pressure PU Foaming Machine

| Name: | High Pressure Pu Foam Machine | Foaming Principle: | High Pressure Air Type |

|---|---|---|---|

| Mixing Ratio Range: | 1:5~5:1(adjustable) | Injection Output (mixing Ratio 1:1): | 110-540g/s |

| Foam Type: | Rigid Foam | Applications: | Floating Plaster Trowel |

| High Light: |

Trowel High Pressure PU Foaming Machine, Concrete Tool trowel making machine, floating plaster trowel making machine |

||

Polyurethane Concrete Tool Trowel Making Machine High Pressure PU Foaming Machine Description of pu foam making machine: Polyurethane material is the abbreviation of polyurethane, the English name is polyurethane, it is a polymer material. Polyurethane is an emerging organic polymer material, known as the "fifth largest plastic", because of its excellent performance, it is widely used in many fields of the national economy. Product application areas involve light industry, chemical industry, electronics, textile, medical, construction, building materials, automotive, national defense, aerospace, aviation, etc. Technical Parameter:

| No. | Item | Technical parameter |

| 1 | Foam application | rigid foam |

| 2 | raw material viscosity(22℃) | POLY ~2500MPas ISO ~1000MPas |

| 3 | injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 110~540g/s |

| 5 | Mixing ratio range | 1:5~5:1(adjustable) |

| 6 | injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | mixing head | four oil hoses,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/min system pressure 10~20MPa |

| 11 | Tank volume | 250L |

| 12 | POLY metering pump | JLB-12 |

| 13 | ISO metering pump | JLB-12 |

| 14 | compressed air needed | Dry,oil free P:0.7Mpa Q:600NL/min |

| 15 | Temperature control system | Heat: 2×9Kw(selectable 3Kw) |

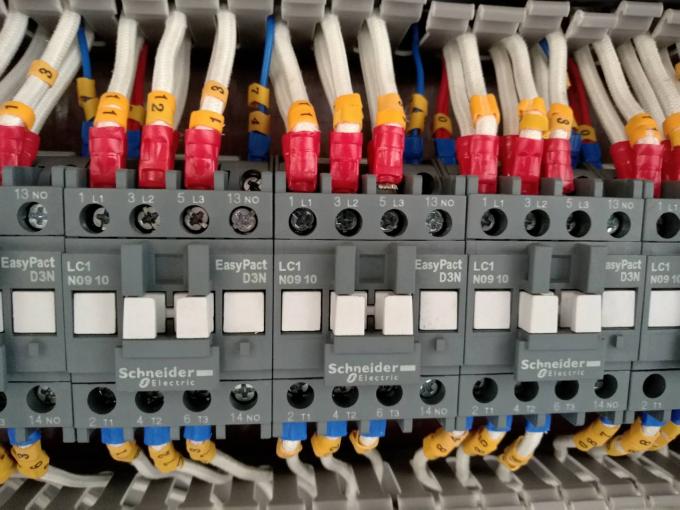

| 16 | Input power | three-phase five-wire 380V |

Polyurethane foaming machine is a special equipment for polyurethane foam infusion foaming. As long as the performance indexes of the polyurethane component raw materials (isocyanate component and polyether polyol component) meet the requirements of the formula. Through this equipment, uniform and qualified foam products can be produced. Application of polyurethane foam injection machine: Polyurethane trowel, also known as PU trowel, is different from the previous wooden or iron trowel. It changes the shortcomings of the previous bulky trowel, inconvenient to use and carry, easy to wear and corrosion. The advantages of the polyurethane trowel are: light weight, high strength, wear resistance, corrosion resistance, insect resistance, and low temperature environment strength, etc., and its performance is better than polyester, glass fiber reinforced plastic and plastic products, which can completely replace wood and iron Quality trowel.

Application of polyurethane foam injection machine: Polyurethane trowel, also known as PU trowel, is different from the previous wooden or iron trowel. It changes the shortcomings of the previous bulky trowel, inconvenient to use and carry, easy to wear and corrosion. The advantages of the polyurethane trowel are: light weight, high strength, wear resistance, corrosion resistance, insect resistance, and low temperature environment strength, etc., and its performance is better than polyester, glass fiber reinforced plastic and plastic products, which can completely replace wood and iron Quality trowel.

Product Features of High Pressure PU Machine:

1. Adopting two layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2. Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3. Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4. Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5. High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6. Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors. Feedbacks of polyurethane injection molding machine