Cornice 450kg/min Low Pressure PU Foaming Machine

| Applicable Industries: | Manufacturing Plant | Processing Type: | Foaming Machine |

|---|---|---|---|

| Condition: | New | Product Type: | Foam Net |

| Machine Type: | Injectio Namchine | Voltage: | 380V |

| Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm | Power (kW): | 168kW |

| Weight (KG): | 1200 KG | Warranty: | 1 YEAR |

| After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | Key Selling Points: | Automatic |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Local Service Location: | Turkey, Pakistan, India |

| Name: | Polyurethane Machine | Filter: | Self-cleaning Filter |

| Material Feeding: | Automatic Feeding System | Control System: | PLC |

| Metering Pump: | Precise Metering | Foam Type: | Rigid Foam |

| Output: | 90~450kg/min | Tank Volume: | 250L |

| Color: | Cream-colored/ Orange/ Blue | Port: | Ningbo For Polyurethane Machine |

| High Light: |

90kg/min Polyurethane Foaming Machine, 450kg/min Low Pressure PU Foaming Machine, 90kg/min Low Pressure PU Foaming Machine |

||

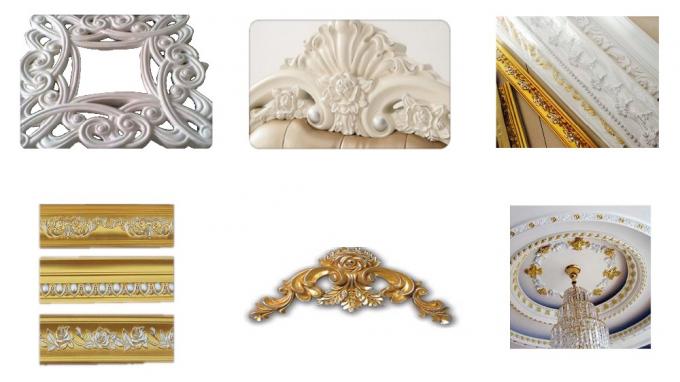

Low Pressure Polyurethane PU Wood Imitation Foam Making Injection Machine For Cornice Application: Polyurethane line is currently the most popular new high-end architectural decoration material in Europe and the United States. It has the following excellent characteristics:

Superior quality: The product does not change its shape, cracks, or rots; it is resistant to corrosion, acid and alkali, and can maintain the stability of the material for many years. No insects, no termites; no water absorption, no water seepage, and can be washed directly.

Convenient construction: The material is lighter, and all products have been painted with white paint, which can be directly pasted, which greatly saves labor and paint.

Easy to process: it can be sawed, planed, filed, installation is almost no waste, economical and environmentally friendly.

Good colorability: Water-based and oil-based paints of various colors can be applied to the surface, and it can last for a long time after coloring. Imitation stone, imitation wood, imitation metal, vivid and vivid.

Green and environmental protection: no radiation, non-volatile. After pyrolysis, it will not produce any harmful gas to the human body.

Excellent craftsmanship: beautiful, durable and delicate products. Large pieces are magnificent and magnificent, while small pieces are delicate and exquisite. Comprehensively enhance the decoration taste.

Wide range of uses: excellent indoor and outdoor performance, suitable for interior and exterior decoration of residences, villas, hotels, American salons, nightclubs, clubs, dance halls, hotels, office spaces, conference halls, etc. Product Description: Polyurethane low-pressure foaming machine is widely used in multi-mode continuous production of rigid and semi-rigid polyurethane products, such as: petrochemical equipment, directly buried pipelines, cold storage, water tanks, meters and other thermal insulation and sound insulation equipment craft products.

| No. | Item | Technical parameter |

| 1 | Foam application | Wood Imitation Cornice |

| 2 | Raw material viscosity(22℃) | POL ~3000CPS ISO ~1000MPas |

| 3 | Injection flow rate | 130-500g/s |

| 4 | Mixing ratio range | 100:50~150 |

| 5 | Mixing head | 2800-5000rpm, forced dynamic mixing |

| 6 | Tank Volume | 120L |

| 7 | Input power | Three-phase five-wire 380V 50HZ |

| 8 | Rated power | About 12KW |

| 9 | Swing arm | Rotatable 90°swing arm, 2.3m (length customizable) |

| 10 | Volume | 4100(L)*1300(W)*2300(H)mm, swing arm included |

| 11 | Color( customizable) | Cream-colored/orange/deep sea blue |

| 12 | Weight | About 1000Kg |

Features of Low Pressure Foam Injection Machine: 1. Accurate measurement, using high-precision low-speed gear pump, with an error of 5‰.

2. The mixing is uniform, and the high-shear mixing head is adopted, and the performance is reliable.

3. The pouring head adopts a special mechanical seal to prevent air leakage and material dumping.

4. The material temperature is stable, the material tank adopts its own heating temperature control system, the temperature control is stable, and the error is <±2℃.

5. The whole machine adopts a 10-inch touch screen and is controlled by a PLC module, which can be poured regularly and quantitatively, and automatically clean and air flush. Main components and parameter specification: Material system consists of material tank, filter tank, metering pump, material pipe, infusion head,cleaning tank.

Material tank: Double interlining heating material tank with insulation outer layer, heart rapidly, low energy consumption. Liner, upper and low head all use stainless 304 material, upper head is precision machinery sealing equipped to make sure the air tight agitation.

Reliable self- cleaning system: Automatically controlled by cleaning solenoid valve and blowing solenoid valve through PC programmable controller.

Spare parts: Head seals, mixer, mixing cup, common tools, instruction book , etc.

Raw Material Formula Solution Support:

We have our own technical team of chemical engineers and process engineers, all of whom have more than 20 years of experience in PU industry. We can independently develop raw material formulas like polyurethane rigid foam, PU flexible foam, polyurethane integral skin foam and polyurea that meet all customer' s requirements.  Packing & Delivery:

Packing & Delivery:

| Packaging | |

| Size | 4100*1250*2300(mm) |

| Weight | 1.2 T |

| Packaging Details | The normal package is wooden box(Size: 2600*1500*2600). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Team:

We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

Our Service:

1. Professional and patient consulting service to help you find the suitable solution.

2. Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3. Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4. Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5. Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6. For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7. For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8. We give an accessory box for free.

9. We offer development solutions for raw material formulations.

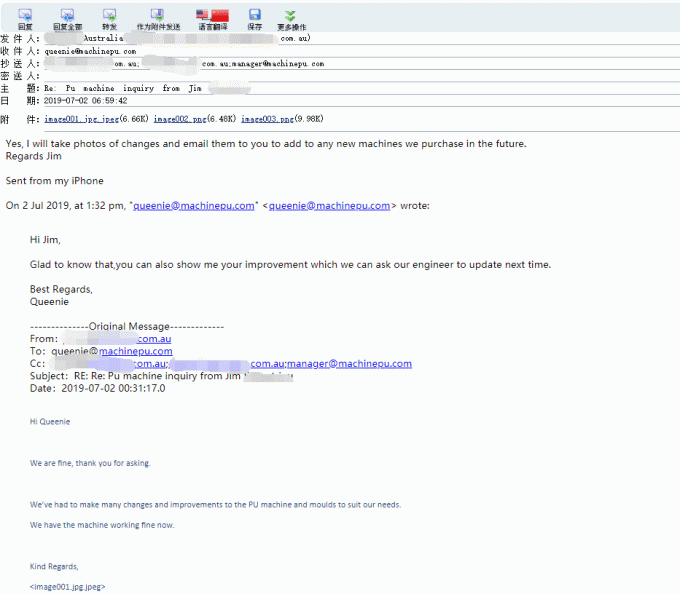

10. If you need to visit the factory, we will arrange for personnel to pick up the airport. Feedbacks: Good Feedback from our Australian client who buy a low pressure PU polyurethane foaming machine.

Good Feedback from our Australian client who buy a low pressure PU polyurethane foaming machine.