Energy Saving Convenient Rigid Surfboard Pu Pouring Machine

| Power (kW): | 9kW | Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm |

|---|---|---|---|

| Product Type: | Foam Net | Processing Type: | Foaming Machine |

| Condition: | New | Output: | 16-66g/s |

| Machine Type: | Foaming Machine | Voltage: | 380V |

| Weight (KG): | 2000 KG | Warranty: | 1 YEAR |

| Key Selling Points: | Automatic | Local Service Location: | Turkey, Pakistan, India |

| Showroom Location: | Turkey, Pakistan, India | Applicable Industries: | Manufacturing Plant |

| Strength 1: | Self-cleaning Filter | Strength 2: | Precise Metering |

| Feeding System: | Automatic | Control System: | PLC |

| Tank Volume: | 250L | Power: | Three-phase Five-wire 380V |

| Name: | Foamed Concrete Chemicals | Port: | Ningbo For High Pressure Machine |

| High Light: |

Surfboard pu pouring machine, Rigid polyurethane pouring machine, Surfboard polyurethane pouring machine |

||

PU Polyurethane Pouring Molding High Pressure Machine For Surfboard Product Description: The polyurethane foaming machine uses two raw materials, POLY and ISO. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

Product Description: The polyurethane foaming machine uses two raw materials, POLY and ISO. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

| No. | Item | Technical parameter |

| 1 | Foam application | Rigid Foam Surfboard |

| 2 | Raw material viscosity(22℃) | POLY ~2500MPas ISO ~1000MPas |

| 3 | Injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 270~1300g/min |

| 5 | Mixing ratio range | 1:5~5:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | Mixing head | Four oil house,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/min System pressure 10~20MPa |

| 11 | Tank volume | 500L |

| 15 | Temperature control system | Heat: 2×9Kw |

| 16 | Input power | Three-phase five-wire 380V |

Product Features of High Pressure PU Machine:

1. Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2. Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3. Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4. Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5. High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6. Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors. Detailed Images:

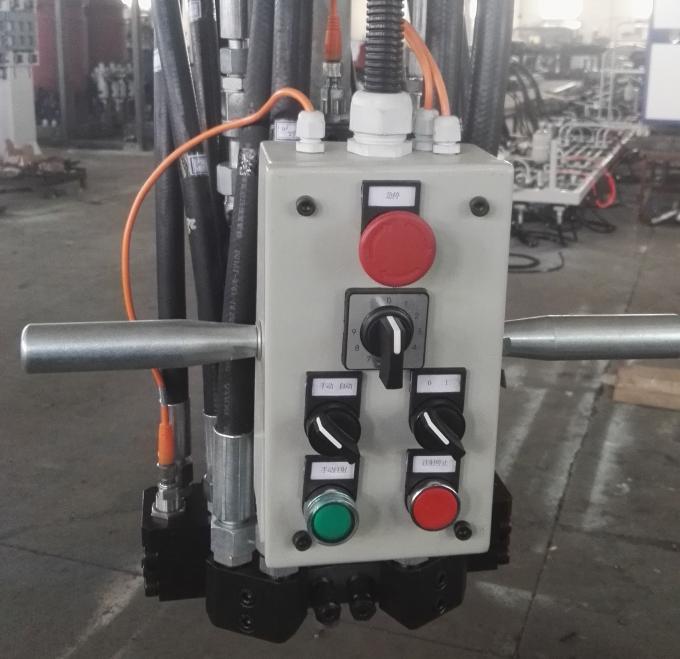

Mixing head

The mixing head adopts floating mechanical seals, and its high shear mixing screw head, which can mix two materials (Polyurethane and Isocyanate) with better performance.The raw materials are stirred at high speed in the mixing chamber by stirring blades to achieve a mixing effect, so that the liquid is uniformly sprayed to form a desired product.

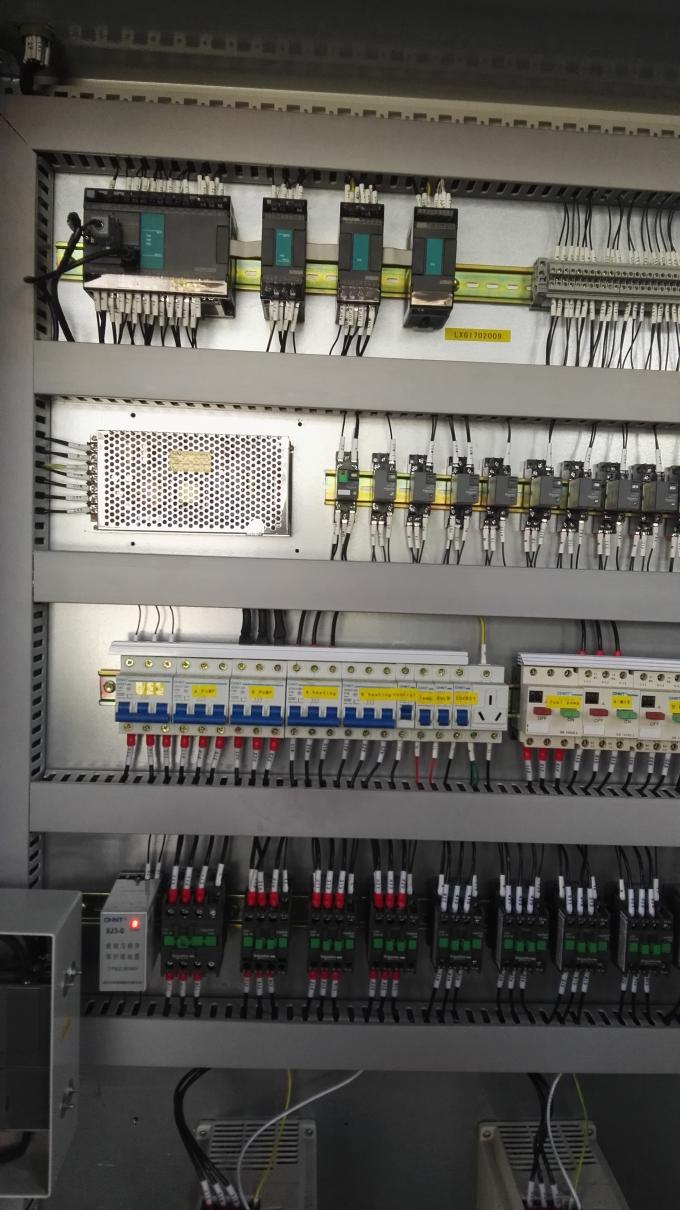

Electrical control system

1. Fully controlled by SCM (Single Chip Microcomputer).

2. Using PLC touch screen computer. Temperature,pressure, revolving speed display system.

3. Alarm function with acoustic warning.

Application: PU as a construction refers to a surfboard built from a Polyurethane blank with Polyester resin, whilst PE refers to a Polyurethane Blank with Epoxy resin. These have long been the standard for most brands, and is the most widely and affordable options still out there. Due to the foams weight and density PU / PE boards sit a little lower in the water, helping to keep your rail under, giving you a nice “knifey” feel when slicing through the waves face. Being a touch heavier also helps them to handle choppy conditions better and are less prone to being bounced around. Sitting lower in the water also has its benefits to barrel riding, providing more hold in hollow waves.  Our Team We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

Our Team We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

Our Service

1. Professional and patient consulting service to help you find the suitable solution.

2. Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3. Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4. Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5. Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6. For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7. For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8. We give an accessory box for free.

9. We offer development solutions for raw material formulations.

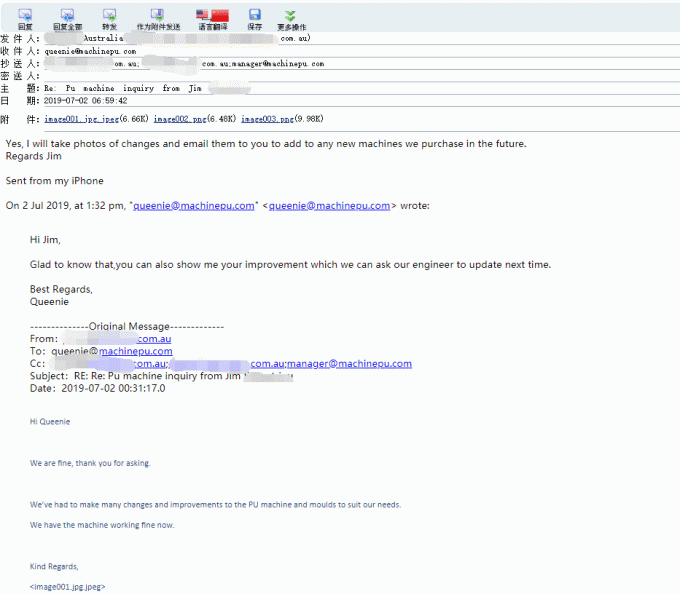

10. If you need to visit the factory, we will arrange for personnel to pick up the airport. Feedbacks  Good Feedback from our Australian client who buy a low pressure PU polyurethane foaming machine.

Good Feedback from our Australian client who buy a low pressure PU polyurethane foaming machine.