High Pressure Liquid Polyurea PU Foam Spray Equipment

| Voltage: | 380V | Processing Type: | Foaming Machine |

|---|---|---|---|

| Condition: | New | Machine Type: | Foaming Machine |

| Dimension(L*W*H): | 910*890*1330 | Power (kW): | 9 |

| Weight (KG): | 116 KG | Key Selling Points: | Easy To Operate |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Showroom Location: | Turkey, Pakistan, India |

| Applicable Industries: | Manufacturing Plant, Construction Works | Marketing Type: | Hot Product 2019 |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 YEAR | Core Components: | Bearing, PLC |

| Name: | Polyurethane Pu Spray Machine | Mix Head: | Mix Evenly, No Bubble |

| Injection Pressure: | 0.01-0.1Mpa | Injection Time: | 0.5~99.99S (correct To 0.01S) |

| Temperature Control: | ±2℃ | Repeated Injection Accuracy: | ±1% |

| Application: | Spray Wall | Equipped Pipe Length: | 15meters Heating Pipe |

| Ratio Between A And B: | 1:1 | Port: | Shanghai For Polyurethane Pu Spray Machine |

| High Light: |

Polyurea PU spray foam machine, 9kW PU Foam Spray Equipment, Polyurea PU Foam Spray Equipment |

||

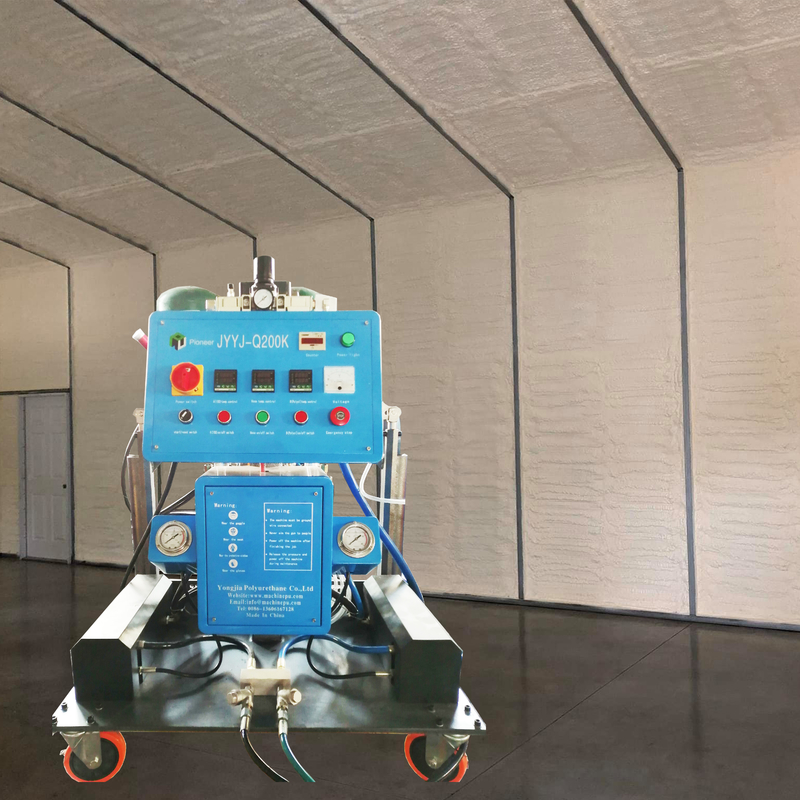

High Pressure Liquid Polyurethane PU Injection Pump Spray Foam Machine Product Description: Pu and Polyurea material has many advantages such as insulation, heat proofing, noise proofing and anti corrosion etc. Widely used in many areas. Environmental friendly and energy saving. The insulation and heat proofing function are better than any other materials. The function of this pu spray foam machine is to extract polyol and isocycanate material. Make them pressurized. So both materials combined by high pressure in the gun head and then spray out spray foam soon.

Product Description: Pu and Polyurea material has many advantages such as insulation, heat proofing, noise proofing and anti corrosion etc. Widely used in many areas. Environmental friendly and energy saving. The insulation and heat proofing function are better than any other materials. The function of this pu spray foam machine is to extract polyol and isocycanate material. Make them pressurized. So both materials combined by high pressure in the gun head and then spray out spray foam soon.

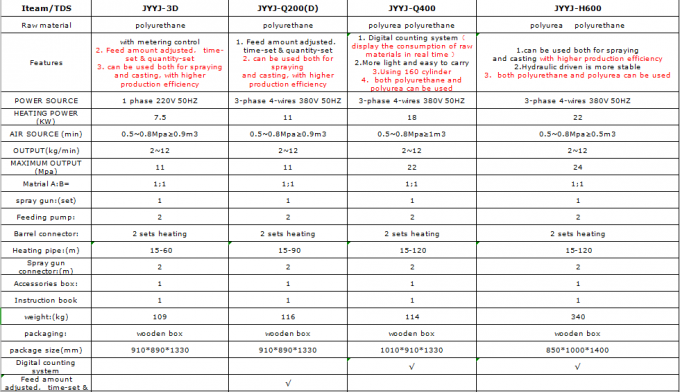

| Iteam/TDS | JYYJ-Q200(D) |

| Raw material | polyurethane |

| Features | 1. Feed amount adjusted, time-set & quantity-set 2. can be used both for spraying and casting, with higher production efficiency |

| POWER SOURCE | 3-phase 4-wires 380V 50HZ |

| HEATING POWER (KW) | 11 |

| AIR SOURCE (min) | 0.5~0.8Mpa≥0.9m3 |

| OUTPUT(kg/min) | 2~12 |

| MAXIMUM OUTPUT (Mpa) | 11 |

| Matrial A:B= | 1;1 |

| spray gun:(set) | 1 |

| Feeding pump: | 2 |

| Barrel connector: | 2 sets heating |

| Heating pipe:(m) | 15-90 |

| Spray gun connector:(m) | 2 |

| Accessories box: | 1 |

| Instruction book | 1 |

| Digital counting system | |

| Feed amount adjusted, time-set & quantity-set | √ |

| Double cyclinder supercharged unit | |

| Hydraulic driven | |

| pneumatic driven | √ |

Main Features of Polyurethane PU Spray Foam Machine:

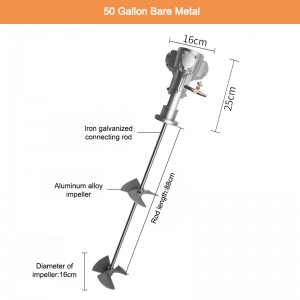

1. Secondary pressurized device to ensure fixed material proportion of equipment, improve product yield;2. With small volume, light weight, low failure rate, easy operation and other great features;3. Feed rate can be adjusted,have time-set,quantity-set features, suitable for batch casting, improve production efficiency;4. Adopting the most advanced ventilation method, guarantee equipment working stability to the maximum;5. Minimizing spraying congestion with multi-feedstock device;6. Multi-leakage protection system to protect the safety of the operator;7. Equipped with emergency switch system, help operator deal with emergencies rapidly;8. Humanized design with equipment operation panel, super easy to get the hang of it;9. The latest spraying gun has great features like small volume, light weight, low failure rate, etc;10. Lifting pump adopts big change ratio method, the winter also can easily feed raw materials high viscosity. Foam Spray Machine Parts:

Spray Gun: Spray and infusion dual-purpose guns, various types of round spray, flat spray and infusion gun cores can be used interchangeably, and the application range is wider. The filtering function of the double-sided filter screen reduces the clogging of the spray gun.

Multifunctional feed pump: For corrosion-resistant parts in a corrosive liquid environment for a long time, 316 stainless steel is specially used instead of other materials such as carbon steel. It is more corrosion-resistant and wear-resistant. The multiple filtering system enables the raw material filtering device to minimize spray clogging.

15 meters heating pipe: The heating pipe adopts imported special material, which makes the pipe heating faster and more balanced in a low temperature environment. The special imported nylon heating tube enhances the flexibility of the pipeline. The unique sensing and heating system ensures that the temperature of the raw materials in the pipeline is balanced and not lost. Related Products  Applications: 1. Insulation & Coating: external wall insulation, internal wall insulation, roof, cold storage, ship cabin, cargo containers,trucks, refrigerated trucks,tank, etc.2. Casting: solar water heaters,tank insulation, cabin, insulation board, security doors, refrigerators, pipes, road construction, packaging, road construction, wall insulation, etc. Packing & Delivery

Applications: 1. Insulation & Coating: external wall insulation, internal wall insulation, roof, cold storage, ship cabin, cargo containers,trucks, refrigerated trucks,tank, etc.2. Casting: solar water heaters,tank insulation, cabin, insulation board, security doors, refrigerators, pipes, road construction, packaging, road construction, wall insulation, etc. Packing & Delivery

| Packaging | ||

| Size | 890(L) * 910 (W) * 1330 (D) | |

| Weight | 120 KG | |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |