PU Polyurethane Foam Packing Machine Fragile Goods Packaging Equipment

PU Polyurethane Foam Packing Machine Fragile Goods Packaging Equipment

Introduction Of On site Packaging Solution:

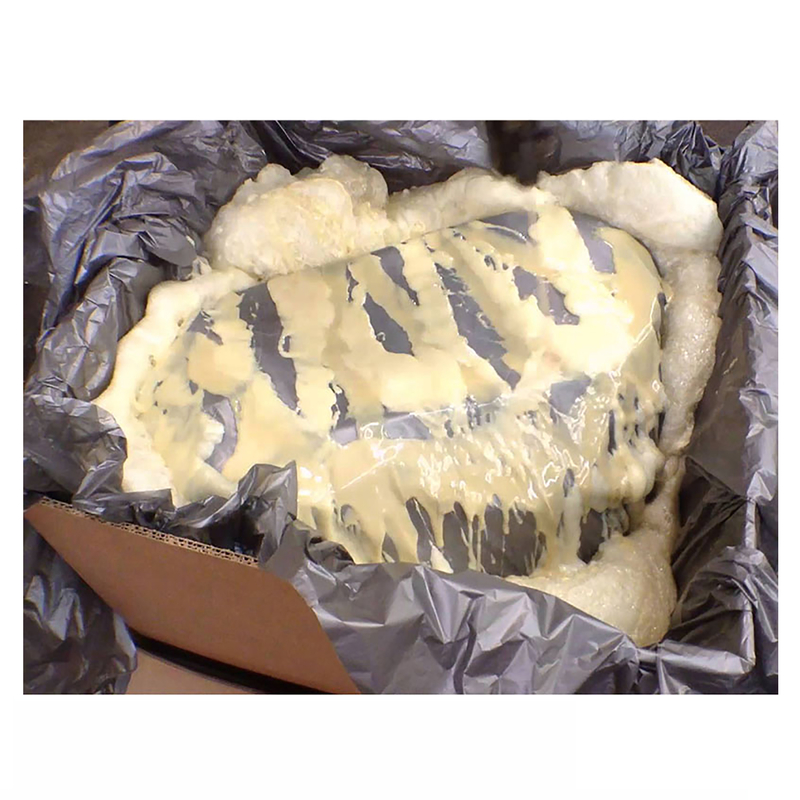

On-demand foam or “foam-in-place” is made in real-time by combining two liquid foams in a bag or liner. The expandable foam packaging mixture rapidly surrounds the product creating a custom, protective mold.

This foam-in-place system is ideal for high volume, medium to large applications that require cushioning or blocking and bracing to protect goods.

Foam in place packing systems feature the most cost-effective, time-efficient foam-in-place packaging technology in the industry. The intuitive equipment design and responsive controls simplify the packaging process, reduce cost and increase productivity.

| Models | YJ-F | Liquid pressure | 1.2-2.3Mpa |

| Power supply | 220V,50Hz,<2500W | Thermoregulation | 0-99°C |

| Air pressure | 0.7-0.8kg/cm2 | Timing scope | 0.01-99.99s |

| Air flow | 0.35m3/min | Flow | 6-8kg/min |

System for feeding raw materials to spray gun, adopts plunger pump with high precision and good abrasion resistance, and comes with a pressure regulating valve block to make the flow and regulation accurate.

Carry materials, heat and preserve heat at the same time. External wrapped with insulation materials to avoid scald caused by careless operation.

Main features of pu foam packing machine:

1. No need to open the mold Use your product as a mold, and when you make a foam cushion, you will package it directly with your product.

2. Save storage space Quickly foam into packaging materials wherever you need them, saving you a lot of storage space and material handling time.

3. Environmental protection The packaging materials are manufactured without the use of Freon CFC or HCFC, harmful metals or other prohibited substances, which can be reused and regenerated. They comply with all national regulations and comply with export requirements in the global certification.

4. Excellent product protection The unmatched cushioning properties of on-site blister packaging ensure the safety of your product during transportation, storage and handling.

5. Wide range of uses Products of different sizes, shapes and weights are used for optimum cushioning, high-speed void filling or high-strength support positioning.

6. Accelerate the packaging process It can be expanded into a protective package in a few seconds, greatly improving production efficiency.

7. Easy to operate The operator can master the operation process and routine maintenance within a few minutes.

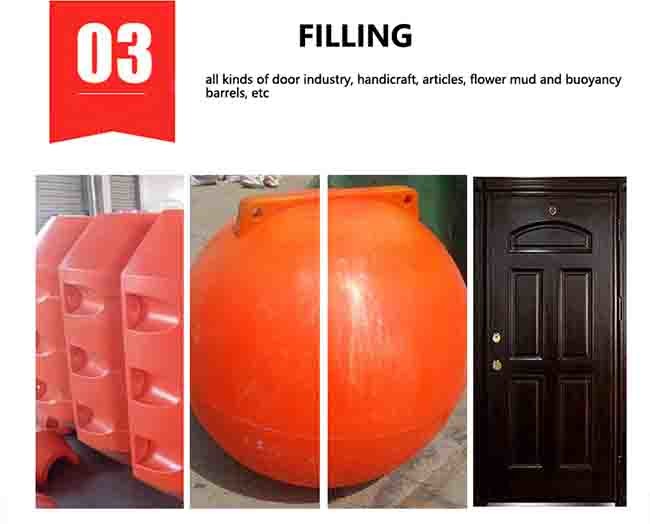

Equipment Functions:

1. Packing: For the packaging of precise instrument, mechanical products, electronic products, pump and valve, artware, ceramics, glassware, lighting products, bathroom accessory, and other kinds of special-shaped fragile goods.

2. Insulation: water dispenser liner, automobile portable electronic refrigerator, electric water heater, freezer,etc.

3. Filling: All kinds of door industry, artware, buoyancy bucket, etc.