Precision Instrument Parts 0.01s Foam In Place Packaging Machine

| Type: | Filling Machine | Applicable Industries: | Manufacturing Plant |

|---|---|---|---|

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Local Service Location: | Egypt, Turkey, Pakistan, India |

| Showroom Location: | Egypt, Turkey, Pakistan, India | Condition: | New |

| Application: | APPAREL, Chemical, Commodity, Machinery & Hardware, MEDICAL | Packaging Type: | CANS, Capsule, Cartons, Case, Stand-up Pouch |

| Packaging Material: | Glass, Metal, Plastic, Wood | Automatic Grade: | Semi-automatic |

| Driven Type: | Pneumatic | Voltage: | 220V/50HZ |

| Dimension(L*W*H): | 1250*650*650mm | Weight: | 80KG |

| Warranty: | 1 YEAR | After-sales Service Provided: | Online Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service |

| Key Selling Points: | Easy To Operate | Name: | Pu Packing Machine |

| Color: | Creamy White | Raw Material: | Polyol And Isocyanate |

| Filling Material: | Polyurethane Foam | Flow: | 6-8kg/min |

| Fluid Pressure: | 1.2-2.3Mpa | Timer Range: | 0.01-99.99S |

| Function: | Packing And Filling | Air Supply: | 0.7-0.8kg/cm2 0.35M3/min |

| Machine Type: | PU Foaming Machine | Port: | Shanghai For Pu Packing Machine |

| High Light: |

0.01s foam in place packaging equipment, 50Hz foam in place packaging equipment, 0.01s Foam In Place Packaging Machine |

||

Polyurethane PU Packaging Machine For Precision Instrument Parts Foam-in-place Packaging System: Foam-in-place packaging system as an economical and practical packaging machine, which saves your space and improves packaging efficiency, and achieves an optimal packaging effect and product image. The advantages of some export products are more prominent. It can provide large-scale products with comprehensive protection of rapid positioning, buffering and space filling in a very short time, ensuring reliable protection during transportation, storage and loading and unloading.

| Models | YJPU | Liquid pressure | 1.2-2.3Mpa |

| Power supply | 220V,50Hz,<2500W | Thermoregulation | 0-99°C |

| Air pressure | 0.7-0.8kg/cm2 | Timing scope | 0.01-99.99s |

| Air flow | 0.35m3/min | Weight | 80kg |

| Flow | 6-8kg/min |

Main features of pu foam packing machine:

1. 6.15 meters heating hoses.

2. The floor type operation platform, easy installation and simple operation.

3. The spear novel structure, small volume, light weight, simple operation and convenient.

4. With computer self-checking system, fault alarm, leakage protector, safe and reliable work.

5. With foam gun heating device, the user of the "gate" and save raw materials working hours.

6. The preset infusion time regularly, shortcut for manual pouring, easy to save time.

7. Fully automatic operation, automatic cleaning, the pipe is not blocked

The best advantage of pu foam packing machine:

Within a very short time to provide rapid positioning for large of manufactured goods, fine buffer and space filling full

protection,Ensure that the product in the transport.The process of storage and loading and unloading and reliable protection.Specifications of pu foam packing machine

Application:

PACKAGING

Various abnormal and fragile articles,such as precise instruments,machines,aircraft instruments,electronice products,communication products,pump valves,pneumatic transmitters,handicraft articles,ceramic utensils,glasses,linghting products,bathing equipments,etc.

HEAT PRESERVING

Water fountain liner,portable electronic refrigerators in cars,vacuum cups,electric water heaters,general equipments,thermal insulation,solar water heaters,freezers,etc.

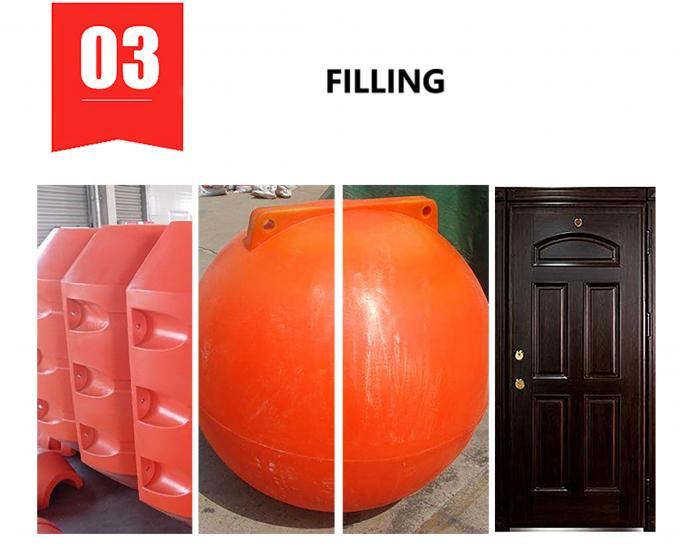

FILLING

All kinds of door industry,handicraft,articles,flower mud and buoyancy barrels,etc. Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Team:

We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

Our Service:

1. Professional and patient consulting service to help you find the suitable solution.

2.Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3.Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4.Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5.Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6.For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7.For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8.We give an accessory box for free.

9.We offer development solutions for raw material formulations.

10.If you need to visit the factory, we will arrange for personnel to pick up the airport.