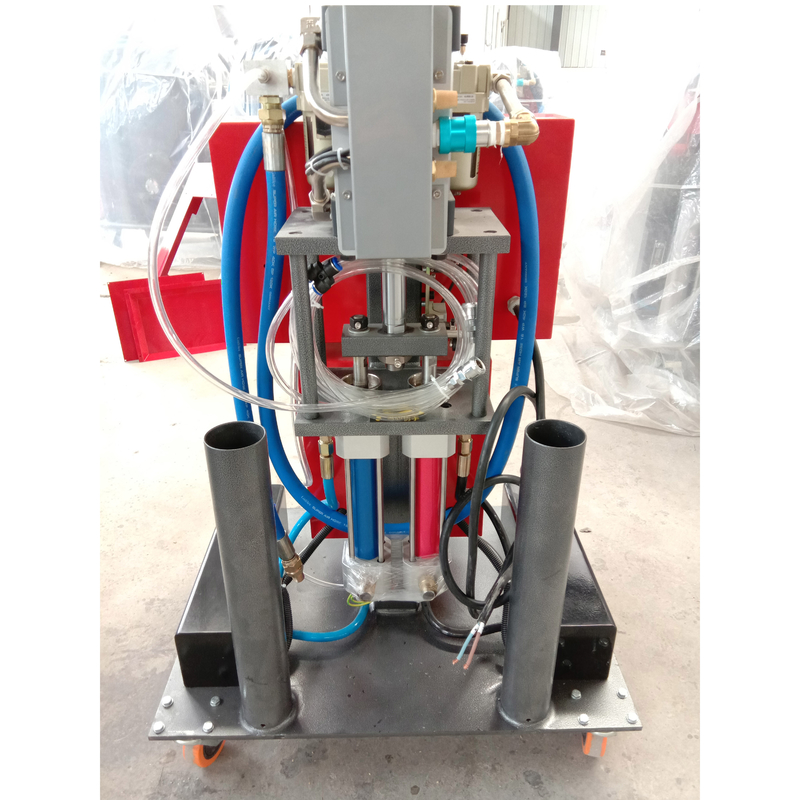

Metering Control 7.5KW Polyurethane Spray Foam Machine

| Machine Type: | Foaming Machine | Power (kW): | 9 |

|---|---|---|---|

| Condition: | New | Product Type: | Foam Net, PU Spray Foam Machine |

| Voltage: | 380V | Dimension(L*W*H): | 910*890*1330 |

| Weight (KG): | 109 KG | After-sales Service Provided: | Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support |

| Key Selling Points: | Easy To Operate | After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Local Service Location: | Turkey, Pakistan, India | Applicable Industries: | Manufacturing Plant, Construction Works |

| Marketing Type: | Hot Product 2020 | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 YEAR |

| Name: | Polyurethane Pu Spray Machine | Mix Head: | Mix Evenly, No Bubble |

| Injection Pressure: | 0.01-0.1Mpa | Injection Time: | 0.5~99.99S (correct To 0.01S) |

| Temperature Control: | ±2℃ | Repeated Injection Accuracy: | ±1% |

| Application: | Spray Wall | Equipped Pipe Length: | 15meters Heating Pipe |

| Ratio Between A And B: | 1:1 | Port: | Shanghai For Polyurethane Pu Spray Machine |

| High Light: |

7.5KW PU foam spray machine, 50HZ Polyurethane Spray Foam Machine, 7.5KW Polyurethane Spray Foam Machine |

||

High Pressure Liquid Polyurethane PU Spray Machine For Insulation And Waterproof Features of Polyurethane Foam Painting Machine 1. Secondary pressurized device to ensure fixed material proportion of equipment, improve product yield;2. With small volume, light weight, low failure rate, easy operation and other great features;3. Feed rate can be adjusted,have time-set,quantity-set features, suitable for batch casting, improve production efficiency;4. Adopting the most advanced ventilation method, guarantee equipment working stability to the maximum;5. Minimizing spraying congestion with multi-feedstock device;6. Multi-leakage protection system to protect the safety of the operator;7. Equipped with emergency switch system, help operator deal with emergencies rapidly;8. Humanized design with equipment operation panel, super easy to get the hang of it;9. The latest spraying gun has great features like small volume, light weight, low failure rate, etc;10. Lifting pump adopts big change ratio method, the winter also can easily feed raw materials high viscosity. Product Description

Features of Polyurethane Foam Painting Machine 1. Secondary pressurized device to ensure fixed material proportion of equipment, improve product yield;2. With small volume, light weight, low failure rate, easy operation and other great features;3. Feed rate can be adjusted,have time-set,quantity-set features, suitable for batch casting, improve production efficiency;4. Adopting the most advanced ventilation method, guarantee equipment working stability to the maximum;5. Minimizing spraying congestion with multi-feedstock device;6. Multi-leakage protection system to protect the safety of the operator;7. Equipped with emergency switch system, help operator deal with emergencies rapidly;8. Humanized design with equipment operation panel, super easy to get the hang of it;9. The latest spraying gun has great features like small volume, light weight, low failure rate, etc;10. Lifting pump adopts big change ratio method, the winter also can easily feed raw materials high viscosity. Product Description

| SPECIFICATIONS FOR JYYJ-3D PU Spray Machine | ||

| Parameter | Raw material | polyurethane |

| Features | 1. With metering control 2. Feed amount adjusted, time-set & quantity- set 3. Can be used both for spraying and casting, with higher production efficiency | |

| Power source | 1- phase 220V 50HZ | |

| Heating power | 7.5KW | |

| Driven mode | pneumatic | |

| Air source | 0.5-0.8 MPa ≥0.9m³/min | |

| Raw output | 2-12 kg/min | |

| Maximum output pressure | 11MPA | |

| Poly and ISO material output ratio | 1:1 | |

| Spare parts | Spray gun | 1 Set |

| Heating hose | 15-120 meters | |

| Spray gun connector | 2 m | |

| Accessories box | 1 | |

| Instruction book | 1 | |

| Gift | Protective suit | 1 set |

| Goggle | 1 set | |

| Gloves | 1 set | |

| Mask | 1 set | |

| Earplug | 1 box | |

Spraying Foam Machine Details

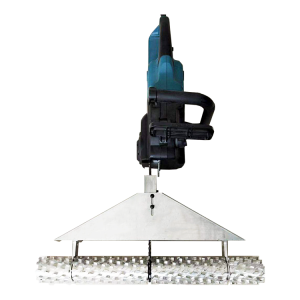

Spray Gun

Two different spray guns for polyurethane foam spray machine, left one for foam injection, right one for foam spraying.

The gas spring is designed of the gun shot ensures the shooting Flexibility.

Self-cleaning air, replacement and maintenance easier and faster.

Heating Horse

The heating horse is designed for polyurethane and polyurea foam spraying and casting, no matter polyurethane rigid foam or flexible foam you use, heated separately with latest wrapped inside heating technology, ensuring the material has best temperature and viscosity before mixing and spraying.

Feeding Pump

Transfer pump are widely used in the industries of chemical, fine chemical, dyeing chemical, and etc and can be applied for transferring mediums such as acid, alkali, salt, oil product, soft drinks, and etc.

These two pump is suitable for polyurethane and polyurea foaming spray equipment.

Moving Wheels

All polyurea and polyurethane spray coating machine is equipped with 2 or 4 swivel casters for easy handling and movement. Why Choose Us!

Raw Material Formula Solution Support: We have our own technical team of chemical engineers and process engineers, all of whom have more than 20 years of experience in PU industry. We can independently develop raw material formulas like polyurethane rigid foam, PU flexible foam, polyurethane integral skin foam and polyurea that meet all customer' s requirements.

Factory Visit Service Support: We have our own polyurethane foam machine workshop with advanced CNC machinery and equipment, all our engineers are engaged into pu field for more than 10 days and support you the most professional machine or production line solution. Our Factory Machine Assembly Center

Machine Assembly Center Product Warehouse

Product Warehouse Awards of our team

Awards of our team