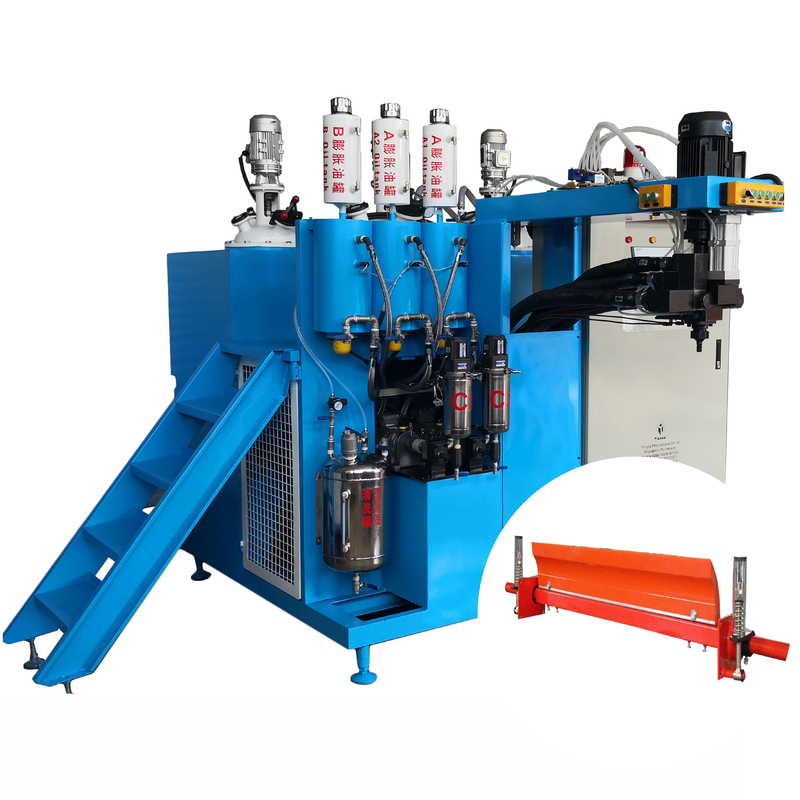

PU Car Bumper Making SS304 Polyurethane Casting Machine

| Power (kW): | 25~31kW | Key Selling Points: | Automatic |

|---|---|---|---|

| Product Type: | Foam Net | Machine Type: | Foaming Machine |

| Voltage: | 380V | Dimension(L*W*H): | 2300*2000*2300 Mm |

| Weight (KG): | 2000 KG | Warranty: | 1 YEAR |

| After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Local Service Location: | Turkey, Pakistan, India | Showroom Location: | Turkey, Pakistan, India |

| Applicable Industries: | Manufacturing Plant | Product Name: | Casting Machine |

| Mix Head: | Mix Evenly, No Bubble | Injection Pressure: | 0.01-0.1Mpa |

| Injection Time: | 0.5~99.99S (correct To 0.01S) | Temperature Control: | ±2℃ |

| Repeated Injection Accuracy: | ±1% | Color: | Deep Blue/cream Color/red |

| Ratio Between A And B: | 1 : 1 | Raw Material: | Polyol And Isocyanate |

| Port: | Ningbo For Polyurethane Foam Injection Machine | ||

| High Light: |

SS304 PU casting machine, CE Polyurethane Casting Machine, SS304 Polyurethane Casting Machine |

||

Polyurethane Elastomer Injection Machine For PU Car Bumper Making Application: Suitable For PU Bumper: Polyurethane buffer is a kind of rubber products with high elasticity and high toughness, which belongs to automobile modification accessories. It is used to install at the coil spring of the automobile suspension system, which mainly serves as a buffer and shock absorber and protects the shock absorber. PU Elastomer Casting Machine Introduction: PU elastomer casting machine is used to produce castable polyurethane elastomers with MOCA or BDO as chain extenders. PU elastomer casting machine is suitable for manufacturing various kinds of CPUs such as seals, grinding wheels, rollers, screens, impellers, OA machines, wheel pulleys, buffers, etc. product.

| No. | Item | Technical Parameter |

| 1 | Injection Pressure | 0.1-0.6Mpa |

| 2 | Injection flow rate | 2-5kg/min |

| 3 | Mixing ratio range | 100:6-18(adjustable) |

| 4 | Injection time | 0.5~99.99S (correct to 0.01S) |

| 5 | Temperature control error | ±2℃ |

| 6 | Repeated injection precision | ±1% |

| 7 | Mixing head | Around 5000rpm (4600~6200rpm,adjustable), forced dynamic mixing |

| 8 | Tank volume | 220L/30L |

| A maximum working temperature | 70~110℃ | |

| B maximum working temperature | 110~130℃ | |

| 9 | Cleaning tank | 20L 304# stainless steel |

| 10 | Metering pump | JR50/JR50/JR9 |

| A1 A2 Metering pump displacement | 50CC/r | |

| B Metering pump displacement | 6CC/r | |

| A1-A2-B-C1-C2 PUMPS MAXIMUM SPEED | 150RPM | |

| A1 A2 agitator speed | 23RPM | |

| 11 | Compressed air requirement | Dry, oil free P:0.6-0.8MPa Q:600L/min(Customer-owned) |

| 12 | Vacuum requirement | P:6X10-2Pa(6 BAR) Speed of exhaust:15L/S |

| 13 | Temperature control system | Heating: 18~24KW |

| 14 | Input power | Three-phrase five-wire,380V 50HZ |

| 15 | Heating power | TANK A1/A2: 4.6KW TANK B: 7.2KW |

| 16 | Total power | 34KW |

| 17 | Working Temperature | Room temperature to 200℃ |

| 18 | Swing arm | Fixed arm, 1 meter |

| 19 | Volume | About 2300*2000*2300(mm) |

| 20 | Color (selectable) | Deep blue |

| 21 | Weight | 2000Kg |

Product Features of PU Elastomer Casting Machine:

High temperature resistant low speed high precision metering pump,accurate measurement,random error within±0.5%. Material output adjusted by frequency converter with frequency conversion motor,high pressure and precision,simple and rapid rapid ratio control. High performance mixing device,adjustable pressure,accurate material output synchronization and even mix;New type mechanical seal structure avoids reflux problem. High-efficiency vacuum device with special mixing head ensures product no bubbles. Adopting electromagnetic heating method to heat transfer oil,efficient and energy saving;Multi-point temp.control system ensures stable temperature,random error<±2°C. Adopting PLC and touch screen man-machine interface to control pouring,automatic cleaning flush and air purge.stable

performance.high operability,which can automatically distinguish,diagnose and alarm abnormal situations as well as display abnormal factors.

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Factory: Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

Our Team:

We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines

Our Service:

1. Professional and patient consulting service to help you find the suitable solution.

2.Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3.Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4.Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5.Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6.For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7.For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8.We give an accessory box for free.

9.We offer development solutions for raw material formulations.

10.If you need to visit the factory, we will arrange for personnel to pick up the airport.