Wall Insulation 9KW Polyurethane Spray Coating Equipment

| Processing Type: | Foaming Machine | Condition: | New |

|---|---|---|---|

| Product Type: | Foam Net | Voltage: | 380v |

| Dimension(L*W*H): | 910*890*1330 | After-sales Service Provided: | Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support, Engineers Available To Service Machinery Overseas |

| Key Selling Points: | Automatic | Applicable Industries: | Manufacturing Plant, Construction Works |

| Name: | Portable Pu Foam Spray Machine | Mix Head: | Mix Evenly, No Bubble |

| Injection Pressure: | 0.01-0.1Mpa | Injection Time: | 0.5~99.99S (correct To 0.01S) |

| Temperature Control: | ±2℃ | Repeated Injection Accuracy: | ±1% |

| Equipped Pipe Length: | 15meters Heating Pipe | Ratio Between A And B: | 1:1 |

| Raw Material: | Polyurethane And Isocyanate | Power: | 9 KW |

| Weight: | 116kg | Selling Units: | Single Item |

| Package Type: | Sea Worthy Wooden Box For Polyurethane Portable PU Spraying Foam Machine Equipment For Wall Insulation | ||

| High Light: |

9KW PU foam spray equipment, 0.01Mpa Polyurethane Spray Coating Equipment, 9KW Polyurethane Spray Coating Equipment |

||

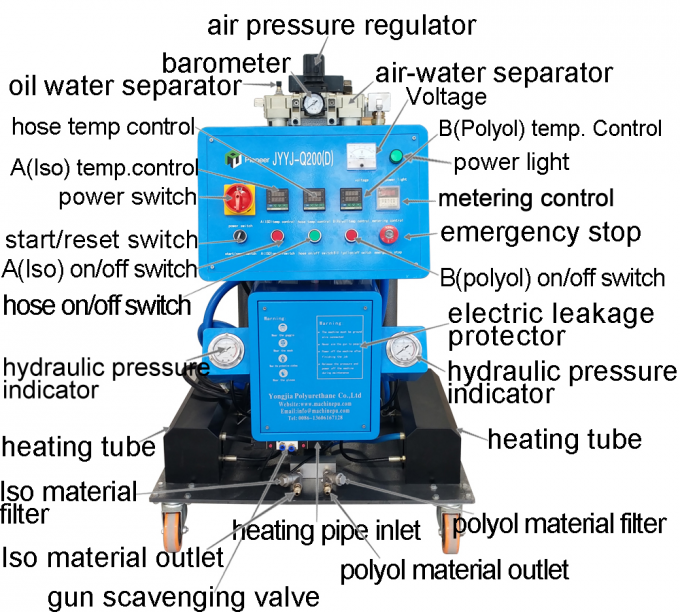

Polyurethane Portable PU Spraying Foam Machine Equipment For Wall Insulation Product Description of pu spray foam machine:JYYJ-Q200 (D) two-component pneumatic Polyurethane Foam Sprayer Machine is used for spraying and pouring, and is used in many fields such as roof insulation of building roofs, cold storage construction, pipeline tank insulation, automobile bus and fishing boat insulation.

Product Description of pu spray foam machine:JYYJ-Q200 (D) two-component pneumatic Polyurethane Foam Sprayer Machine is used for spraying and pouring, and is used in many fields such as roof insulation of building roofs, cold storage construction, pipeline tank insulation, automobile bus and fishing boat insulation.

| SPECIFICATIONS FOR JYYJ-Q200(D) PU Spray Machine | ||

| Parameter | Raw material | polyurethane |

| Features | 1. Feed amount adjusted, time-set & quantity-set 2. Can be used both for spraying and casting, with higher production efficiency |

|

| Power source | 1- phase 220V 50HZ | |

| Heating power | 7.5KW | |

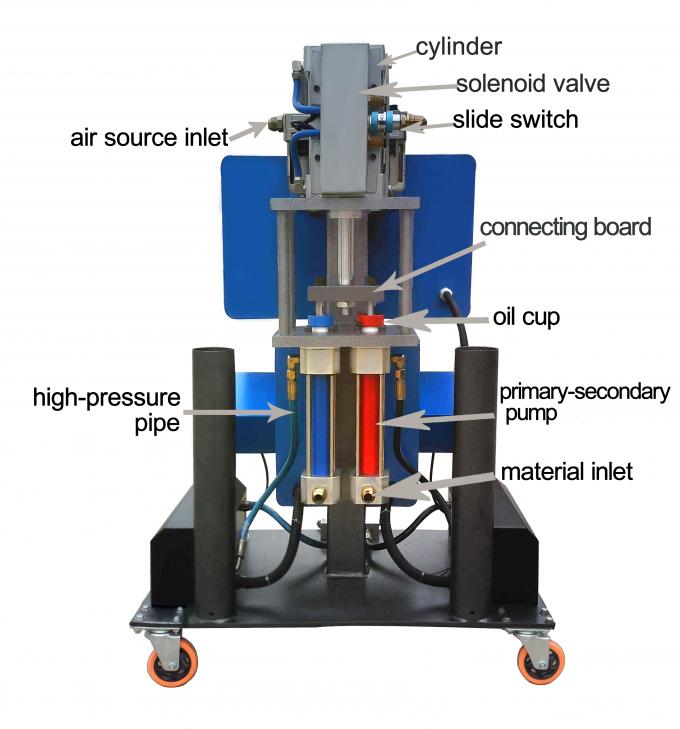

| Driven mode | pneumatic | |

| Air source | 0.5-0.8 MPa ≥0.9m³/min | |

| Raw output | 2-12 kg/min | |

| Maximum output pressure | 11MPA | |

| Poly and ISO material output ratio | 1:1 | |

| Spare parts | Spray gun | 1 Set |

| Heating hose | 15-120 meters | |

| Spray gun connector | 2 m | |

| Accessories box | 1 | |

| Instruction book | 1 | |

| Gift | Protective suit | 1 set |

| Goggle | 1 set | |

| Gloves | 1 set | |

| Mask | 1 set | |

| Earplug | 1 box | |

Main Features of Polyurethane PU Spray Foam Machine:

1. With 160 cylinder pressurizer, easy to provide sufficient work pressure;2. Small size, light weight, low failure rate, easy operation, easy to move;

3. The most advanced air change mode maximally ensures the equipment stability;4. Quadruple raw material filter device maximally reduce blocking issue;5. Multiple leakage protection system safeguard operator's safety;6. Emergency switch system fasten the dealing with emergencies;7. Reliable and powerful 380v heating system can heat up materials to ideal state rapidly to ensure normal construction in cold region;8. Digital display counting system can accurately know about the raw material consumption status in time;9. Humanization setting equipment operation panel, easy operation mode;10. The lifting pump has big mix ratio adjusting range, which can easily feed high viscosity material in cold weather.Detailed Images

Related Products

Related Products

| with metering control 2. Feed amount adjusted, time-set & quantity-set 3. can be used both for spraying and casting, with higher production efficiency |

1. Digital counting system( display the consumption of raw materials in real time ) 2.More light and easy to carry 3.Using 160 cylinder 4. both polyurethane and polyurea can be used |

1.can be used both for spraying and casting with higher production efficiency 2.Hydraulic driven is more stable 3. both polyurethane and polyurea can be used |

|||

| 7.5 | 18 | 22 | |||

| 11 | 22 | 24 | |||

| 1 | 1 | 1 | |||

| 2 | 2 | 2 | |||

| 2 | 2 | 2 | |||

| 1 | 1 | 1 | |||

| 1 | 1 | 1 | |||

Applications 1. Insulation & Coating: external wall insulation, internal wall insulation, roof, cold storage, ship cabin, cargo containers,trucks, refrigerated trucks,tank, etc.2. Casting: solar water heaters,tank insulation, cabin, insulation board, security doors, refrigerators, pipes, road construction, packaging, road construction, wall insulation, etc. Packing & Delivery

| Packaging | ||

| Size | 890(L) * 910 (W) * 1330 (D) | |

| Weight | 120 KG | |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

FAQ1.Are you factory or trading company?

FAQ1.Are you factory or trading company?

We are professional factory in PU industry with more than 10 years experience, covering high pressure pouring machine,low pressure foaming machine, pu spraying foam machine,pu elastomer casting machine and production line for flexible foam products like PU shoe /sole/insole,anti-fatigue mat, memory pillow, elastic stress ball, car seat and cushion,pu slow rebound ear plugs; also rigid foam products production line: PU decorative molding crown cornice line, float trowel making line, cold storage panel production line, sandwich panel production line, last not the least, elastomer product: forklift wheel casting line, coal sieve screen select line and so on.

2.Where is your factory ?

Our Factory is located in Wuxi city, Jiangsu Province.

3.How can i get your factory?

By air: You can take a plan to WUXI airport from China, if you fly from Korea ,Japan, USA, Singapore, Taiwan, Thailand you will can directly fly to us.

By Train: You can stop at WUXI station, Not WUXI EAST station.

4.Do you provide pick-up service?

Yes, of course. If you are in Wuxi airport or station, we can arrange a special car to pick you up directly to our factory.

5.What is the PU raw material used with this polyurethane/polyurea foam casting machine?

Polyurethane which has two components polyol and isocyanate(poly and iso/mdi). Polyurea also can be used which helps to waterproofing and Anticorrosion and rust prevention. Polyurethane can be divided into two kinds, flexible foam and rigid foam. And flexible foam or rigid foam also has two kinds, open cell foam and closed cell foam.

6.If I need to develop a special PU raw material formula solution based on my product, can you provide it?

Yes, we can. We have technical team of chemical engineers and process engineers, all of whom have more than 20 years of experience in PU industry. We can independently develop raw material soluation like polyurethane rigid foam, polyurethane flexible foam, polyurethane integral skin foam and polyurea to meet customer' s requirements.

7.What is the application of PU foam machine?

PU spray foaming machine has two functions:

Spraying: building exterior wall coating, interior wall coating, roof spray, cold spray, cold storage spray, cabin coating, tank body coating, industrial anti corrosion, etc.

Casting: solar water heater, insulation water tank, cabin, roller shutter door, security door, refrigerator, pipe joints, product packaging, highway construction, wall sound insulation, etc.

PU polyurethane foam injeciton machine can make pu rigid foam products like pu crown molding, pu bed sets, pu plastering float, pu coldroom panel; pu flexible foam products like car seat cushion and car headsets, memory foam pillow, slow rebound ear plugs, pu stress ball and kids toy; pu elastomer products like forklift wheel, rollers, sieve screen and so on.

You need to tell us specific machine application and budget, to spray or cast, then we can recommend suitable machine for you.

8.How long is your polyurethane foam casting machine warranty?

1 year. Within one yea, if it is not man-made damage, we will provide free replacement parts, but the shipping cost needs to be paied by the customer.

9.How to solve the polyurethane foaming machine failure?

For pu spraying machine: If there are quality problems with accessories during the one-year warranty period, we can provide replacement parts for free. If there are operations or other problems, you can send photos or videos to us, we will consult our engineers to help you solve the problem.